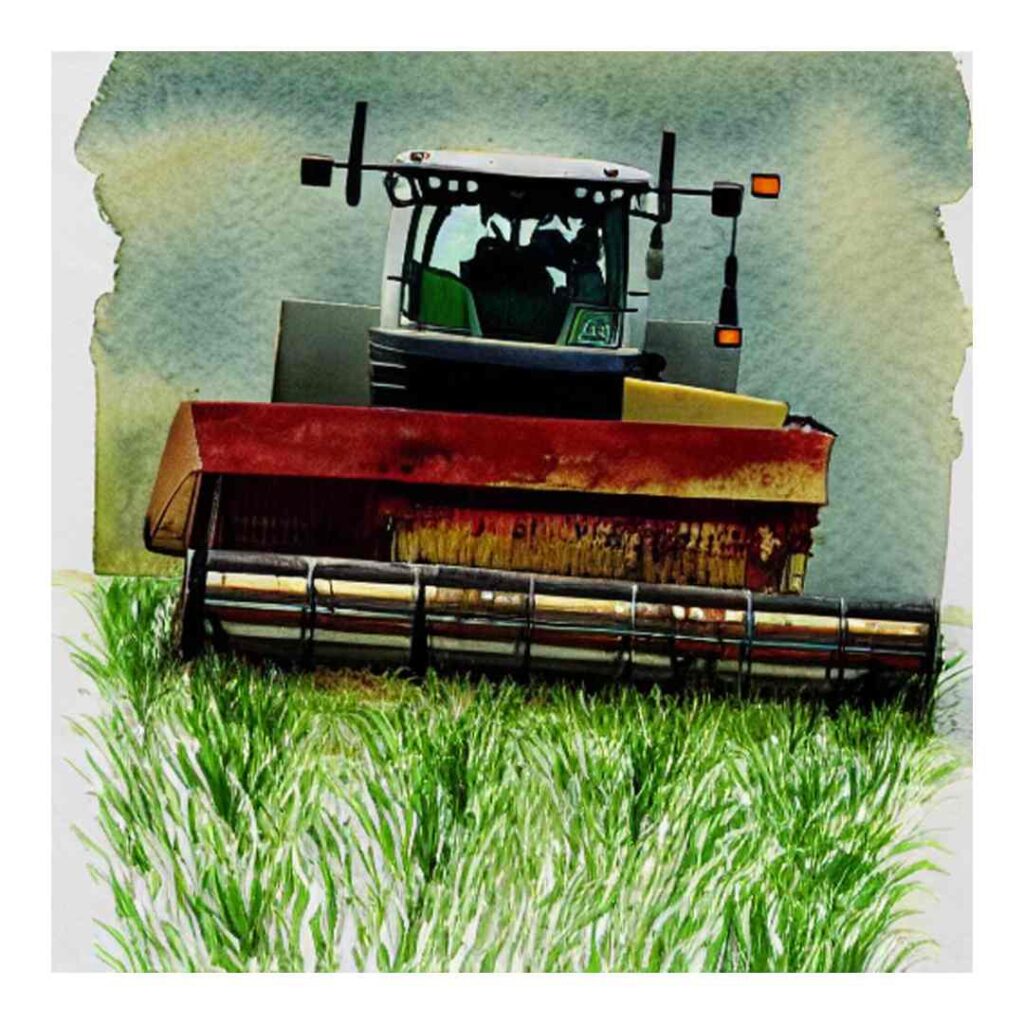

Combine harvesters have revolutionized farming efficiency and productivity. Let’s explore the principle parts of a combine harvester and delve into the function of each component.

Cutting Platform

At the front of the combine harvester is the cutting platform, also known as the header. This component serves as the entry point for the crop, enabling efficient cutting and gathering of the standing crop. The cutting platform is available in various configurations, such as a rigid cutter bar or a flexible draper, depending on the crop type. By adjusting the cutting height and width, farmers can adapt the combine harvester to different crops, ensuring an optimal harvest.

Reel

The reel is a critical component mounted on the front of the cutting platform. It consists of a series of tines or bats that rotate rapidly, gently sweeping the crop into the cutting mechanism. The reel helps to prevent crop lodging and assists in the uniform feeding of the crop into the combine harvester, optimizing the efficiency of the harvesting process.

Threshing Mechanism

The threshing mechanism is responsible for separating the grain from the crop’s stalks and husks. It typically consists of a rotating cylinder equipped with sharp teeth or rasp bars. As the crop enters the threshing mechanism, the teeth or bars separate the grain from the straw through a combination of impact, friction, and pressure. The separated grain falls through the cylinder, while the straw and chaff are expelled from the rear of the combine harvester.

Separation System

The separation system is designed to further separate the grain from the remaining material after threshing. It utilizes a series of sieves, shaking and airflow to remove any residual straw, chaff, and broken grains. This process ensures the harvested grain is clean and of high quality, ready for further processing or storage. Adjustments to the separation system allow farmers to adapt to different crop conditions and maximize the overall efficiency of the combine harvester.

Grain Cleaning System

Following the separation process, the grain cleaning system further enhances the quality of the harvested crop by removing impurities such as dirt, small stones, and broken grains. It typically employs a combination of sieves, aspiration, and gravity separation techniques. The cleaned grain is then conveyed to the grain tank, ready for storage or subsequent transport.

Straw Management System

As a byproduct of the harvesting process, the straw must be managed efficiently. Combine harvesters are equipped with a straw management system that offers several options. Farmers can choose to evenly spread the straw over the field, bale it for various purposes, or collect it for other uses such as animal bedding or bioenergy production. Effective straw management reduces soil erosion, improves soil health, and promotes sustainable farming practices.

Powertrain and Controls

To propel the combine harvester and operate its various components, a robust powertrain system is employed. This usually consists of a powerful diesel engine, transmission, and hydraulic systems. The controls, located in the operator’s cab, enable the adjustment of various machine settings, such as rotor speed, clearance, and fan speed. The integration of advanced technology in modern combine harvesters allows for precise and efficient operation, optimizing productivity and reducing operator fatigue.

So we see that from the cutting platform and reel that facilitate crop entry, to the threshing and separation mechanisms that extract the grain, the principle parts of a combine harvester work in harmony to streamline the harvesting process.